years of

experience

M2

Built-up area

We have a strong R&D team,and we can develop and produce Plastic Valve according to the drawings or samples the customers offered.

We are manufacturer, so we can offer the good price and good Valve fittings directly.

We have our own testing lab and the advanced and complete inspection equipment,which can ensure the quality of the Plastic Valves.

We are located in Ningbo Port area,so it is very convenient and efficient to ship goods to any other countries.

The company owns the abundant technical force and testing Means, gather the advanced technical advantages and precise manufacture equipments ,assemble a group of the technicians who are capable of researching into;developing and producing the complicateds and machine tools, It Iays asolid guarantee to the equipment quality.

We aim to meet all our customers’ request by good quality and service. Welcome your inquiry and visits!

In the field installation of industrial fluid control systems, the orientation of an automatic Butterfly Valve is a critical factor that dictates the long-term stability of the system. Many engineers prioritize piping layout while overlooking the profound impact that the Stem axis orientation has on...

In the world of industrial fluid control, a common pitfall in system design is the assumption that an automatic Butterfly Valve must share the same nominal diameter as the existing pipeline. While this "one-size-fits-all" approach simplifies installation by avoiding the use of reducers, it frequentl...

Socket (Slip) Connection Socket connection is one of the most common methods for ROUND PVDF EQUAL TEE. Each end of the tee is slightly enlarged to form a socket, into which the pipe is inserted. Adhesive or heat fusion is then used to secure the joint. This connection provides good sealing performan...

Overview of PVDF Material Properties ROUND PVDF EQUAL TEE is made of Polyvinylidene Fluoride (PVDF), a high-performance fluoropolymer. PVDF offers excellent chemical resistance, high temperature stability, and mechanical durability. It is widely used in chemical, pharmaceutical, and food industry pi...

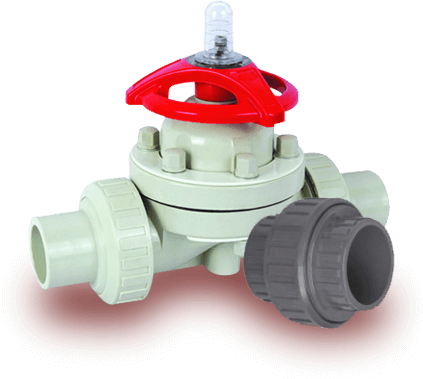

In industrial processes involving abrasive particles, high-viscosity fluids, fibrous media, or crystallizing substances, valve wear resistance and anti-clogging capability are critical to system reliability. Compared with ball valves, gate valves, and globe valves, flanged diaphragm valves exhibit d...

Flanged diaphragm valves are widely used in chemical processing, pharmaceuticals, water treatment, and high-purity industries. When applied in vacuum systems, operating conditions differ fundamentally from pressure service. Load direction, sealing behavior, and material stress states change signific...